The Of Custom Plastic Extrusions

Wiki Article

Plastic Extruded Profiles Fundamentals Explained

Table of ContentsThe Best Guide To Plastic Extrusion CompaniesExamine This Report on Extrusion Of PlasticsCustom Plastic Extrusions Things To Know Before You Get ThisThe Ultimate Guide To Custom Plastic Profiles

Just like any manufacturing procedure, the extruded account will differ a little during the procedure necessitating resistances on key dimensions. Tolerances on plastic extrusions effect fit as well as feature, and also the finest time to start checking out tolerance requirements is during the preliminary design phase. By functioning with Formtech early while doing so, we can provide style for making assistance including tolerance demands.For a much more thorough explanation about exactly how resistances effect rates, and also a basic resistance overview, please visit this site. Mass density is specified as the weight per device quantity of the plastics acquired by Formtech for usage in custom-made extrusion applications. Mass thickness influences circulation and feed rates on the extruder, and variants wholesale thickness of the plastic will trigger variants in dimension so it is a vital factor to consider for custom-made extrusion production procedures We discussed back pressure above, as well as the relevance of having the ideal amount of back pressure during the extrusion procedure for physical residential property control (custom extrusion manufacturer).

Once the plastic compound exits the extrusion pass away in a pressed form, the compound will loosen up, or increase somewhat. This is described as die swell. Die swell is product certain, implying for instance a vinyl (PVC) material will certainly experience a different die swell than a Polyethylene or Polypropylene substance.

In the extrusion process cleansing materials out of barrels, screws and also plastic extrusion tooling takes time and also enhances price (https://www.reverbnation.com/artist/k3ll3rpl4st8). If material adjustments are being made on the line from one task to the next, this could entail getting rid of as well as cleansing the die, pulling the screw on the machine to tidy, and brushing out the barrel of the machine while the screws are out.

The smart Trick of Plastic Extrusion Manufacturers That Nobody is Talking About

Actually, the purging materials are so steady they can even be left in the extrusion pass away throughout storage, returned on the extruder the following time the job requires to run, and also started without time consuming cleaning. The normal substance will certainly press the purge out of the die when it leaves.

There are actually two methods that can be made use of to accomplish this feeding procedure - https://packersmovers.activeboard.com/t67151553/how-to-connect-canon-mg3620-printer-to-computer/?ts=1667541302&direction=prev&page=last#lastPostAnchor. The product can be contained in a receptacle straight over the feed-throat of the extruder as well as fed by gravity. The screws will after that absorb the maximum quantity of material they can with every transformation of the device, as well as this is called flood feeding.

The flights of the screw are not entirely full of every revolution of the machine. This is called starve feeding of the extruder, and also supplies some benefits to the extrusion service technician in specific situations. By not filling up the screw channel completely, it supplies even more control to the professional, and also eliminates a few other variables that can accompany flooding feeding.

The Greatest Guide To Custom Extrusion Manufacturer

For each change of a solitary screw machine, there is some slippage back over the trips of the screw. This slippage is helpful for mixing of products and colorants, however it produces a possibility for some rising and variation with the screw transformation. With this being the situation, differing pressures as product comes off the screw can create this processing problem for the extrusion professional.Call today or e-mail at [email protected] for more details.

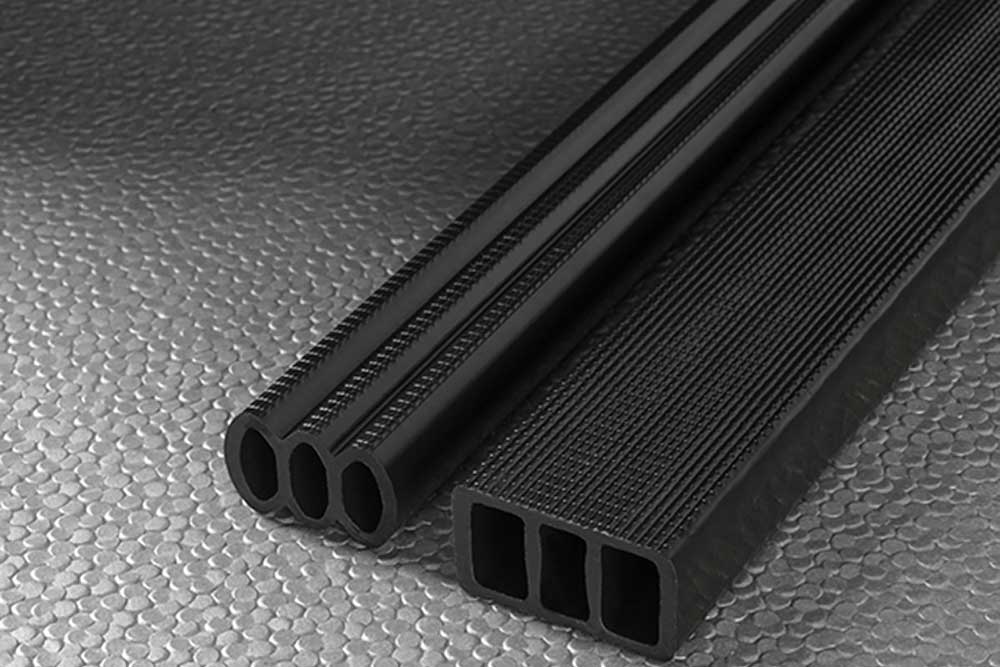

Such a variety of items and also uses represents the vast array of suitable products and also flexibility that the extrusion process pays for in developing custom profiles to satisfy your specific requirements. The plastic profiles created in the extrusion process can be either versatile or rigid. Both offer advantages for various usage instances (https://www.pubpub.org/user/john-wynn).

Some Known Incorrect Statements About Plastic Extrusion Companies

While it inevitably never ever succeeded at its designated function, it however located regular usage in the automobile market in other means, many thanks to its high fluid resistance and outstanding sealing efficiency. Automotive components commonly made from Santoprene consist of weather seals, bumpers, cable television jacketing, and a lot more. Santoprene TPV's remarkable sealing building likewise makes it particularly helpful in construction, where it can be made use of to make window seals, tubing, electric connectors, and also caster wheels (plastic extrusion companies).We utilize innovative innovation in order to develop the precise kind of extruded product you require. We are excited to start collaborating with you soon!.

Production quality products is as vital to us as achieving the highest possible standards for customer support. At the leading edge of our solution are use this link professional and also devoted staff members that meet daily obstacles with innovative concepts - plastic extrusion profiles. Client e-mail Customized accounts/ forms Twin Materials Hollows Rods Tubes Angles Bindings Brackets Caps Stations Clips Edgings Insulators J-Retainers/ J-Clips Moldings Retainers Seals Sleeves Spacers Straps T-moldings Tapes Tracks Cold Temperature Level Efficiency Color Matched Dual-Durometer Ease of Setting Up Embossed Fire Resistant Flexible High Gloss Heat Performance Interlocking Locking Matte Non-Contact Food Grade Ribbed Break Fit Stiff Strength Textured Weatherability Aerospace Home Appliance Air/Water/Pollution Control Automotive Building Products Concrete Building And Construction Electric Grass & Yard Logistics/ Transportation Marine Office Systems Point of Acquisition (POP) Display Numerous Solutions Can Be Taken Care Of In-Line to Remove Secondary Operations Adhesive/Transfer Tape Application Cut to Size Reducing Exploration Embossing Warmth Sealing Laminating Punching Transmitting Slotting Special Packaging Welding AIAG Automotive Industry Action Group ASME American Culture of Mechanical Designers ASTM American Culture for Screening as well as Products DOT Department of Transportation FDA Food and also Medicine Management FMVSS Federal Car Security Specifications MIL-STD Military Specifications SAE Culture of Automotive Engineers UL Underwriters Laboratories ISO International Company for Standardization.

Report this wiki page